Properties of Propane

Formula C3H8

Boiling Point, ºF -44

Specific Gravity of Gas (Air=1.00) 1.50

Specific Gravity of Liquid (Water=1.00) 0.504

Lbs. per Gallon of Liquid at 60º F 4.20

BTU per Gallon of Gas at 60º F 91502

BTU per Lb. of Gas 21548

BTU per Cu. Ft. of Gas at 60º F 2488

Cu. Ft. of Vapor (at 60º F) Gal. 36.38

Cu. Ft. of Vapor (at 60º F) Lb. 8.66

Latent Heat of Vaporization at Boiling Point BTU/Gal. 773

Combustion Data: Cu. Ft. Air Required to Burn 1 Cu. Ft. Gas 23.86

Flash Point, ºF -156

Ignition Temperature in Air, ºF 920-1120

Maximum Flame Temperature in Air, ºF 3595

Limits of Flammability Percentage of Gas in Air Mixture; At Lower Limit – % 2.15

At Upper Limit – % 9.6

Octane Number (ISO-Octane=100) Over 100

Vapor Pressure of LP Gases

| Temperature (°F) | Approximate Pressure (PSIG) |

| -40 | 3.6 |

| -30 | 8 |

| -20 | 13.5 |

| -10 | 23.3 |

| 0 | 28 |

| 10 | 37 |

| 20 | 47 |

| 30 | 58 |

| 40 | 72 |

| 50 | 86 |

| 60 | 102 |

| 70 | 127 |

| 80 | 140 |

| 90 | 165 |

| 100 | 196 |

| 110 | 220 |

Approximate BTU Input For Some Appliances

| Appliance | Approximate Input (BTU per Hour) |

| Range, free standing, domestic | 65,000 |

| Built-in oven or broiler unit, domestic | 25,000 |

| Built-in top unit, domestic | 40,000 |

| Water Heater, (Quick Recovery) automatic storage– | |

| 30 Gallon Tank | 30,000 |

| 40 Gallon Tank | 38,000 |

| 50 Gallon Tank | 50,000 |

| Water Heater, automatic instantaneous | |

| (2 gal. per minute) | 142,800 |

| (4 gal. per minute | 285,000 |

| (6 gal. per minute) | 428,400 |

| Refrigerator | 3,000 |

| Clothes Dryer, Domestic | 35,000 |

| Gas Light | 2,500 |

| Gas Logs | 30,000 |

Vaporization Rate – 100 Lb. Propane Cylinders (Approximate)

| Lbs of Propane in Cylinder | Maximum Continuous Draw in BTU Per Hour At Various Temperatures in Degrees F. | ||||

| 0°F | 20°F | 40°F | 60°F | 70°F | |

| 100 | 113,000 | 167,000 | 214,000 | 277,000 | 300,000 |

| 90 | 104,000 | 152,000 | 200,000 | 247,000 | 277,000 |

| 80 | 94,000 | 137,000 | 180,000 | 214,000 | 236,000 |

| 70 | 83,000 | 122,000 | 160,000 | 199,000 | 214,000 |

| 60 | 75,000 | 109,000 | 140,000 | 176,000 | 192,000 |

| 50 | 64,000 | 94,000 | 125,000 | 154,000 | 167,000 |

| 40 | 55,000 | 79,000 | 105,000 | 131,000 | 141,000 |

| 30 | 45,000 | 66,000 | 85,000 | 107,000 | 118,000 |

| 20 | 36,000 | 51,000 | 68,000 | 83,000 | 92,000 |

| 10 | 28,000 | 38,000 | 49,000 | 60,000 | 66,000 |

This chart shows the vaporization rate of containers in terms of the temperature of the liquid and the wet surface area of the container. When the temperature is lower of if the container has less liquid in it, the vaporization rate of the container is a lower value.

Vaporization of ASME Storage Containers

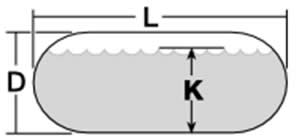

Determining Propane Vaporization Capacity “Rule of Thumb†Guide for ASME LP-Gas Storage Containers Where

DÂ = Outside diameter in inches

LÂ = Overall length in inches

K = Constant for percent volume of liquid in container

|

% of Container Filled |

K Equals |

*Propane Vaporization Capacity at 0°F (in BUU/hr.) |

| 60 | 100 | D X L X 100 |

| 50 | 90 | D X L XÂ 90 |

| 40 | 80 | D X L XÂ 80 |

| 30 | 70 | D X L XÂ 70 |

| 20 | 60 | D X L XÂ 60 |

| 10 | 45 | D X L XÂ 45 |

*These formulae allow for the temperature of the liquid to refrigerate to -20ºF (below zero), producing a temperature differential of 20ºF for the transfer of heat from the air to the container’s “wetted†surface and then into the liquid. The vapor space area of the vessel is not considered. Its effect is negligible.

LP-Gas Regulators

The regulator truly is the heart of an LP-Gas installation. It must compensate for variations in tank pressure from as low as 8 psig to 220 psig – and still deliver a steady flow of LP-Gas at 11†w.c. to consuming appliances. The regulator must deliver this pressure despite a variable load from intermittent use of the appliances. The use of a two-stage system offers the ultimate in pin-point regulation. Two-stage regulation can result in a more profitable LP-Gas operation for the dealer resulting from less maintenance and fewer installation call-backs.

Single Stage/Twin-Stage Regulation

NFPA 58 (1998) states that single stage regulators shall not be installed in fixed piping systems. This requirement includes systems for appliances on RVs, motor homes, manufactured housing, and food service vehicles. In these cases a twin-stage regulator must be used. The requirements do not apply to small outdoor cooking appliances, such as gas grills, provided the input rating is 100,000 BTU/hr or less.

Two Stage Regulation

Two-Stage regulation has these advantages: Uniform Appliance Pressures

The installation of a two-stage system–one high pressure regulator at the container to compensate for varied inlet pressures, and one low pressure regulator at the building to supply a constant delivery pressure to the appliances–helps ensure maximum efficiency and trouble-free operation year round. Two-stage systems keep pressure variations within 1†w.c. at the appliances.

Reduced Freeze-ups/Service Calls

Regulator freeze-up occurs when moisture in the gas condenses and freezes on cold surfaces of the regulator nozzle. The nozzle becomes chilled when high pressure gas expands across it into the regulator body. Two-stage systems can greatly reduce the possibility of freezeups and resulting service calls as the expansion of gas from tank pressure to 11†w.c. is divided into two steps, with less chilling effect at each regulator. In addition, after the gas exits the first-stage regulator and enters the first-stage transmission line, it picks up heat from the line, further reducing the possibility of second-stage freeze-up.

Economy of Installation

In a twin-stage system, transmission line piping between the container and the appliances must be large enough to accommodate the required volume of gas at 11â€w.c.. In contrast, the line between the first and second-stage regulators in two-stage systems can be much smaller as it delivers gas at 10 psig to the second stage regulator. Often the savings in piping cost will pay for the second regulator. In localities where winter temperatures are extremely low, attention should be given to the setting of the first stage regulator to avoid the possibility of propane vapors recondensing into liquid in the line downstream of the first-stage regulator. For instance, if temperatures reach as low as -20ºF, the first-stage regulator should not be set higher than 10 psig. If temperatures reach as low as -35ºF, the setting of the first-stage regulator should not be higher than 5 psig. As an additional benefit, older single-stage systems can be easily converted to two-stage systems using existing supply lines when they prove inadequate to meet added loads.

Allowance for Future Appliances

A high degree of flexibility is offered in new installations of two stage systems. Appliances can be added later to the present load– provided the high pressure regulator can handle the increase– by the addition of a second low pressure regulator. Since appliances can be regulated independently, demands from other parts of the installation will not affect their individual performances.